In a world where consumerism is at its peak, the presentation of proper packaging and preservation of products are more critical than ever. At Brandt Box, we’re passionate about packaging and helping companies thrive. Let’s delve into the intricate and fascinating realm of packaging. Our experts have put together this guide to help you unbox the multifaceted world of packaging, covering everything from its definition to types, functions, and significance.

Table of Contents

- Introduction to Packaging

- The Definition of Packaging

- A Brief History of Packaging

- The Difference Between Packing and Packaging

- The Three Main Types of Packaging

- The Materials Used in Packaging

- Most Popular Types of Packaging Supplies

- Labeling in Packaging

- The Role of Packaging in Marketing

- The Packaging Design Process

- Packaging Technology and Trends

Introduction to Packaging

From getting a package on your doorstep to opening a new product, packaging has become an integral part of our daily lives. Despite this, few people truly understand the depth and complexity behind this seemingly simple concept. A product’s packaging does much more than just wrap and protect goods; it plays a pivotal role in:

- Marketing strategies

- Conveying brand image

- Ensuring product safety

- Offering convenience to consumers

In short, the silent salesman, as packaging is often called, significantly influences a product’s success or failure.

The Definition of Packaging

So, what do we mean by packaging? Packaging refers to the process and materials used to enclose and protect products, and present goods for distribution, sale, storage, and use. It’s the science, art, and technology of designing and producing packages that serve multiple purposes, such as:

- Containing the product

- Preserving its integrity

- Communicating relevant information

Packaging can range from simple paper bags to complex, engineered solutions.

Importance of Packaging

Packaging plays a critical role in various aspects of a product’s sales journey, from the manufacturer to the end consumer. Its importance is outlined through its four primary functions:

— Protection

One of the most fundamental roles of packaging is to protect the product against physical damage, contamination, and other types of tampering. Good packaging:

- Keeps products safe during transportation and storage

- Preserves their quality and condition

- Protects consumers by ensuring that the product they purchase is in its original, untouched state

In certain industries, like food and pharmaceuticals, this protective function is crucial. It safeguards the health and well-being of foods, medicines, and other related substances.

— Information

Packaging is a silent yet efficient communicator. It provides essential information to consumers, such as:

- The product’s name

- Ingredients or components

- Usage instructions

- Manufacturing and expiration dates

- Warnings if needed

Moreover, it communicates brand identity and values to help consumers connect with the brand on an emotional level.

— Promotion

Packaging is a powerful marketing tool. An innovative and attractive package can:

- Grab a customer’s attention

- Draw them in

- Ultimately influence their buying decisions

In crowded retail spaces, packaging materials often serve as a product’s first point of direct contact with potential customers. It’s a pivotal component in promotional strategies and can make or break how successful a brand becomes.

— Convenience

Finally, good packaging offers convenience. It:

- Simplifies transportation, handling, storage, and display of products

- Facilitates easy usage, opening, closing, and disposal for consumers

- Can be tailored to fit many contexts and user needs

For example, consider how convenient these are; single-serve packages for on-the-go consumers, easy-open options for elderly users, or resealable packages to less waste and maintain product freshness.

A Brief History of Packaging

Understanding the past helps us appreciate the present and anticipate the future, and packaging history is no exception. Let’s trace the timeline of food packaging, from the dawn of civilization to the present day.

- Prehistoric times: The concept of packaging has been with us since our early ancestors started using natural materials like leaves, shells, and animal skins to store and transport food and other essentials.

- 3000-1500 BC: As human civilization advanced, so did the packaging materials and techniques. The Ancient Egyptians were among the first to utilize glass for packaging, primarily for storing perfumes. They also made pottery containers.

- 105 AD: The invention of paper by the Chinese revolutionized the world of packaging. Paper offered a lightweight, flexible, and easy-to-produce option for packaging various items.

- The 1800s: The Industrial Revolution in the 19th century brought significant changes to packaging, with the introduction of canning to preserve food and the invention of the cardboard box.

- Early 20th century: Packaging entered the age of plastics, with the invention of materials like cellophane, PVC, and polystyrene. This era also witnessed the introduction of the pop-top can and the Tetra Pak.

- Mid-20th century: The post-war period was a golden age for packaging innovation, with the advent of shrink wrap, bubble products, and the aseptic packaging technique.

- Late 20th — Early 21st century: As environmental concerns gained prominence, the focus shifted toward sustainable and recyclable packaging. Concepts such as biodegradable packaging and smart packaging started to gain traction.

- Present day: Today, the packaging industry combines tradition and innovation. While the fundamental purpose of packaging remains unchanged, continuous technological advancements are pushing the boundaries of what packaging can do. Now, the focus is on eco-friendly materials, intelligent and active packaging, personalization, and user experience.

From ancient pots to today’s smart packaging, the history of packaging is a testament to human ingenuity and adaptability. As we move forward, it’ll continue to evolve and reflect changes in society, technology, and consumer preferences. The packaging industry is ripe for disruption, with exciting developments ahead in areas like smart packaging, biodegradable materials, and personalized packaging.

The Difference Between Packing and Packaging

While “packing” and “packaging” are often used interchangeably in casual conversation, there’s a distinct difference between them in the world of supply chain, packaging machinery, and logistics. It’s important to understand this difference to effectively product protection and presentation.

— Packing

Packing refers to the process of arranging, organizing, and protecting products during transportation, warehousing, and logistics. It’s more about the safe and efficient storage of items, particularly in a shipping context. It ensures that the products remain intact and undamaged during their journey from the manufacturer to the retailer or directly to the customer.

Examples of packing include:

- Using styrofoam peanuts or bubble products to fill the space in a shipping box.

- Using wooden crates or pallets for transporting large or heavy items.

- Using cardboard boxes to group several items together for bulk transportation.

— Packaging

On the other hand, packaging is more focused on the product’s presentation and protection at the point of sale and use. It’s about how a product is presented to the customer, with emphasis on design, aesthetics, information transmission, and user convenience.

Examples of packaging include:

- The design of a cereal box, with its attractive graphics, brand logo, nutritional information, and easy-to-open-and-close top.

- The plastic wrap or foil seal that keeps food items fresh.

- The user-friendly bottle design of a soft drink, with a twist-off cap and contour shape for easy handling.

In summary, while both packing and packaging have the overarching goal of product protection, they have different applications. Packing primarily concerns the safe transport of products, while packaging focuses on product presentation, branding, and customer interaction. Both aspects are vital to the overall product experience and successful journey from manufacturer to consumer.

The Three Main Types of Packaging

In the product packaging realm, we generally distinguish between three key types of transit packaging, each serving a distinct purpose in the product’s journey from producer to consumer: primary, secondary, and tertiary packaging.

— Primary Packaging

Primary packaging is the layer of packaging that directly contacts the product. This type of packaging is crucial as it directly impacts both usability and appeal to the customer. In addition to safeguarding the product, primary packaging often plays a significant role in the consumer’s product experience, as it provides essential information and contributes to the product’s branding.

For example:

- A soda can is a form of primary packaging, as it directly houses the beverage.

- The wrapper around a candy bar or the bottle containing shampoo also falls into this category.

- Blister packs for over-the-counter medications protect each pill and provide a means for consumers to access one dose at a time.

— Secondary Packaging

Secondary packaging is the next layer that groups one or more primary packaged products. It helps protect the product during transit and may also be used to display the product attractively on retail shelves. This type of packaging provides more protection for individual units and helps group similar products together.

Examples of secondary packaging include:

- A cardboard box containing several primary packaged products, like a 6-pack of soda cans or a box of individually wrapped granola bars.

- Display boxes used in retail environments to group and display similar products.

- The branded box that your online order comes in that contains several individual items.

— Tertiary Packaging

Tertiary packaging, often called transport packaging, is designed to protect large quantities of various types of products during storage and transportation. It groups secondary packages and supplies into larger units for efficient handling and shipping.

Examples of tertiary packaging include:

- Shipping cartons that contain multiple secondary packages.

- Pallets of goods shrink-wrapped together for transport.

- Crates or large boxes are used for bulk shipping.

Remember that each layer of packaging serves a distinct purpose and collectively ensures that the product reaches the consumer safely and in good condition, while also fulfilling marketing, informational, and regulatory requirements.

The Materials Used in Packaging

One of the most important decisions in the product packaging process is choosing the right material. The type of material used can impact several factors, including product protection, cost, environmental impact, and user experience. Here are some of the most commonly used packaging types and materials:

— Paper and Carton

Paper and cartons are some of the most versatile and widely used materials in packaging due to their flexibility, cost-effectiveness, and eco-friendliness. They’re commonly used for primary and secondary packaging applications. Paper bags, cardboard boxes, milk cartons, and cereal boxes are common examples.

Key advantages of recycled paper and carton packaging include:

- They can be easily printed on, offering a vast scope for creative branding and product information.

- They’re lightweight which reduces shipping costs.

- They’re environmentally friendly and widely recyclable.

— Plastic

Plastic is another commonly used packaging material due to its flexibility, durability, weight, and resistance to moisture and contaminants. Plastic packaging takes many forms such as bottles, shrink wrap, clamshells, and pouches.

Notable advantages of plastic packaging include:

- It’s highly versatile and can be molded into many shapes and sizes.

- It provides excellent barrier protection against moisture, gases, and light.

- Many plastic types are recyclable, though the recyclability level varies by type and local recycling capabilities.

— Glass

Glass packaging is typically used for products that need a strong barrier against contaminants, heat, and external influences, such as food, beverages, and pharmaceuticals. It’s chosen for its premium look and feel, as well as its high level of recyclability.

Benefits of glass packaging include:

- It’s chemically inert, meaning it won’t interact with the product inside so it can be used with sensitive products.

- It has a high-end aesthetic appeal.

- It’s 100% recyclable and can be reused without loss of purity or quality.

— Metal

Metal, such as aluminum and steel, is often used in packaging for its durability and protective properties. Examples include beverage cans, food tins, aerosol containers, plastic films, and metal caps.

The main advantages of metal packaging include:

- It offers excellent physical protection and barrier properties.

- It can withstand high temperatures, making it suitable for sterilization processes.

- It’s widely recyclable, with metal cans being one of the most recycled packaging forms.

— Fibrous Materials

Fibrous materials, like corrugated fiberboard and molded pulp, are widely used for secondary and tertiary packaging. They’re known for their strength, cushioning properties, and environmental benefits. Some examples of common packaging materials include shipping boxes, egg cartons, and protective packaging inserts.

Key benefits of fibrous materials in packaging include:

- They offer strong, yet lightweight protection for products.

- They have excellent cushioning and shock absorption properties.

- They’re made from renewable resources and are often recyclable or compostable.

When selecting the appropriate packaging material, always consider the nature of the product, the intended user experience, the environmental impact, and the cost implications. The best choice will balance all these factors to deliver optimal product protection and presentation.

Most Popular Types of Packaging Supplies

Packaging supplies come in a wide variety, each suited for different purposes and offering unique advantages. Here are some of the most popular packaging supply types:

— Corrugated Boxes

Corrugated boxes are a staple in the industry. Their robustness, affordability, and versatility make them a top choice for businesses. They come in different sizes and shapes to accommodate various products.

— Padded Mailers

Ideal for smaller items that require an extra layer of protection, padded mailers are both lightweight and secure. They often come with a self-seal closure for ease of use.

— Bubble Products

Bubble products are an essential protective packaging supply. It’s great for wrapping around delicate items to protect them from shocks during transit.

— Shrink Wrap

Shrink wrap is used to tightly secure products together. It’s

often used in the food and beverage industry or to bundle multiple units of a product.

— Packing Tape

An essential in packaging, packing tape ensures boxes are securely sealed. It even comes in various strengths to match the weight of the package.

— Stretch Film

Used primarily in pallet wrapping, stretch film is a highly stretchable plastic film that secures items tightly. It’s especially useful for bulk shipments.

— Kraft Paper

Kraft paper is a versatile packaging supply that can be used for wrapping, void fill, or even crafting custom-made envelopes.

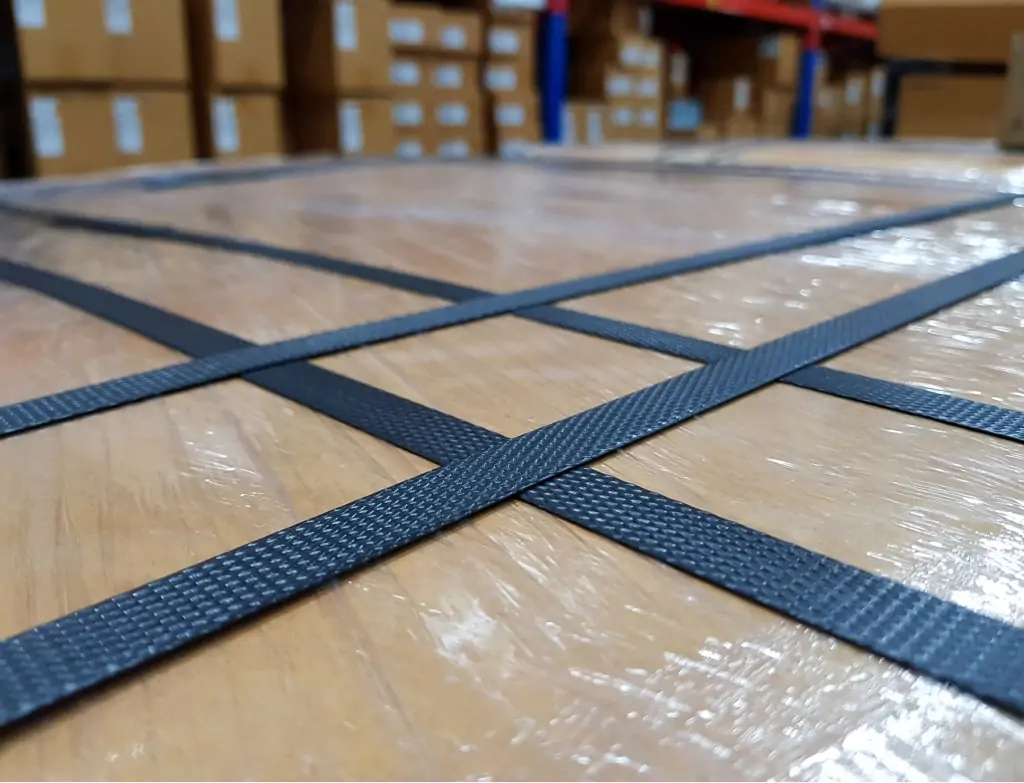

— Strapping

Strapping is used to secure heavy goods, especially in palletized loads. It’s available in different materials like polyester, polypropylene, and steel, each ideal for different applications.

— Labels

Labels serve as the identification of the package. They can carry various information like the recipient’s address, barcodes, or special handling instructions.

Each packaging supply has its unique benefits and uses. It’s key that you understand what works best for your product. Whether you need to protect fragile goods, ensure safe transit, or make your product stand out, there’s a packaging supply to meet your needs.

Labeling in Packaging

Labeling plays an integral role in product packaging. It helps convey vital product information and aids in marketing, regulation compliance, and enhancing consumer engagement. Labels are of several different types, each serving a unique purpose. Let’s explore the common types of labels in consumer packaging:

— Brand Labels

Brand labels are designed to showcase the brand’s identity prominently. They typically display the brand name, logo, and sometimes the tagline. When executed seamlessly, brand labels can increase brand recognition and create a strong visual identity for the product. They’re often colorful and aesthetically appealing to attract consumer attention.

Key attributes of brand labels include:

- Clear, high-quality logo representation

- Consistency with the brand’s color scheme and fonts

- The potential inclusion of the brand’s tagline or motto

— Descriptive Labels

Descriptive labels provide detailed information about the product, such as its features, usage instructions, and benefits. These labels are especially important for products that require assembly or special handling instructions, like electronics or furniture. They can also explain the product’s unique selling points and add to its appeal.

Typical features of descriptive labels are:

- Clear, concise product descriptions

- Instructions for use, assembly, or installation

- Information about the product’s benefits or unique features

— Grade Labels

Grade labels are used to indicate the quality or grade of a product. They’re often seen in products like eggs, meat, and produce to help consumers make informed decisions based on their preferences and budget.

Key components of grade labels are:

- A clear indication of product grade or quality level

- Consistency with industry or regulatory grading standards

- Easy visibility to assist consumer decision-making

— Informative Labels

Informative labels contain the information required by regulatory bodies. This includes nutritional facts on food products, warnings on potentially harmful products, or fabric care instructions on clothing. These labels are crucial for consumer safety, legal compliance, and informed purchase decisions.

Typical information on these labels includes:

- Nutritional information for food products

- Warnings or safety instructions

- Care or handling instructions

— Promotional Labels

Promotional labels are used to draw attention to promotions, offers, or special product features. Examples include “New,” “Improved,” “Sale,” or “Limited Edition” labels. They’re designed to attract attention and prompt quick purchase decisions.

Promotional labels often feature:

- Bold, attention-grabbing colors and fonts

- Information about the promotion or special feature

- A sense of urgency to encourage immediate purchases

If you want to stand out, effective labeling can significantly enhance the overall impact of your packaging. It provides essential information, reinforces your brand, and engages customers in meaningful ways. Make sure to invest time and effort in designing and applying the right labels to your product packaging.

The Role of Packaging in Marketing

Business owners know that in today’s modern, competitive business environment, packaging plays a crucial role in marketing strategy. It’s much more than just a container to hold and protect the product. Packaging communicates the brand, influences purchasing decisions, and offers a unique way to stand out from the competition. Here’s an overview of how packaging aids in marketing:

— Brand Recognition

Packaging goes beyond the protection of the product inside, it helps in building brand recognition. Consistent use of specific colors, logos, typography, and design elements makes your brand easily identifiable on the shelves. This familiarity leads to customer loyalty and repeat purchases. As consumers associate certain colors and designs with your brand, your packaging becomes an extension of your brand identity.

— Differentiation

In a marketplace overflowing with similar products, unique and appealing packaging can help a product stand out. Creative, well-designed packaging differentiates a product from its competitors and attracts customers’ attention. It can be the determining factor that prompts consumers to choose your particular product, over others.

— Communication of Product Information

Packaging serves as a critical medium for communication. It provides consumers with important product information such as ingredients, nutritional facts, usage instructions, and manufacturing details. Packaging can also communicate product benefits, special features, and promotional offers, all of which can influence the purchase decision.

— Influence on Purchasing Decisions

First impressions matter, and in most cases, the package is the first touchpoint a consumer has with the product. Eye-catching packaging design can entice consumers to pick up the product, and informative labeling can convince them to purchase. If you have aesthetically pleasing and practical packaging, it can create a positive product experience that leads to customer satisfaction and loyalty.

— Sustainability and Brand Image

Today’s consumers are increasingly conscious of environmental sustainability. Offering eco-friendly packaging can enhance a brand’s image, satisfy customer demand, promote, and position the brand as a responsible and forward-thinking entity. Green packaging solutions can help attract eco-conscious customers, fostering brand loyalty among this growing demographic.

The Packaging Design Process

The packaging design process is a sequence of steps that transforms an initial idea into a tangible, functional package. This process varies depending on the specific project requirements, but it usually includes the following stages:

— Briefing

The briefing stage sets the foundation for the entire project. In this step, the company outlines its needs and goals for the new packaging line, taking into account factors like target audience, brand identity, product characteristics, cost limitations, and regulatory requirements. The brief may also specify the need for sustainable materials or other specific attributes. The design team uses this brief as a guide throughout the design process.

— Concept Development

Once the brief is defined, the creative process begins. The design team develops multiple concepts based on the brief. This stage often involves brainstorming sessions, sketches, and mood boards to generate a wide range of ideas before narrowing down to a few strong options. Both aesthetics and functionality are considered in this stage.

— Design and Artwork

After the best concepts are selected, they’re further developed into more detailed designs. The designers create artwork for the packaging, considering elements such as color, typography, images, and informational text. They also work on the physical structure of the packaging, ensuring that it’ll adequately protect the product and work well in a retail environment.

— Testing

The testing phase is critical. It ensures the effectiveness and feasibility of the design. Prototypes are made and tested for various factors, including durability, user-friendliness, production cost, and market acceptance. The testing phase might include focus groups or surveys to gauge consumer reaction. Based on feedback, designs may be refined or revised.

— Production

Once the design has been finalized and thoroughly tested, it goes into production. The production process includes printing, cutting, folding, wrapping, and assembling the packages. Quality control measures are implemented at this stage to ensure that all packages meet the manufacturers’ standards. After production, the packaging is ready to be filled with the product and distributed to retailers.

As you can tell, the packaging design process requires a careful balance of creativity, technical knowledge, and market understanding. Its ultimate goal is to create packaging that not only protects the product but also connects with consumers and enhances the brand.

Packaging Technology and Trends

Packaging technology has come a long way and continues to evolve rapidly. Its innovations aim to improve product protection, consumer experience, and environmental impact. Here are some of the significant trends:

— Smart Packaging

This is a dynamic field where packaging can interact with consumers, offering added value. Examples include QR codes that provide product information or augmented reality (AR) features that enhance user experience.

— Sustainable Packaging

As environmental concerns increase, brands are moving toward using more sustainable materials like biodegradable plastics, recycled materials, and alternatives to single-use plastic.

— Active and Intelligent Packaging

This involves packaging other products that can monitor the condition of products inside the product, extend shelf-life, or even interact with consumers. Examples are freshness indicators, time-temperature indicators, and antimicrobial packaging.

— Personalized Packaging

Advances in digital printing technology make it easier for brands to create personalized delivery packages for customers. As a result, they can enhance the consumer experience and strengthen brand loyalty.

Conclusion

Whether you realize it or not, packaging plays an essential role in today’s marketplace. It’s not just about protecting the product, but also about communicating with consumers, promoting the brand, and providing convenience. The field of packaging is continually evolving, driven by advances in technology and changing consumer expectations. As the world becomes more sustainable and digitally integrated, the importance of packaging will only continue to grow.

Feel inspired to make a change in your approach? Begin your journey with us at BrandtBox and elevate your product packaging to the next level. If you have any questions or need personalized advice, don’t hesitate to contact us. The future of packaging is here. Are you ready to unbox it?