Table of Contents

When it comes to packaging, polymer plastics offer a range of advantages over other options, including their lightweight nature, resistance to breakage, and ability to be molded into various shapes and sizes; they’re highly versatile for packaging different products- a must for most businesses.

There are two commonly used polymers: polyethylene and polypropylene. Understanding the difference between these two materials is crucial for businesses looking to make informed decisions about their packaging solutions.

In this article, we’ll use our expertise to delve into the characteristics and properties of polyethylene and polypropylene, exploring their differences and highlighting their respective benefits. By gaining a clear understanding of these materials, businesses can make the right choice for their specific packaging needs, ensuring the highest level of quality, protection, and cost-effectiveness.

If you still have questions by the end, feel free to contact our team at Brandt Box!

What Are Polyethylene and Polypropylene?

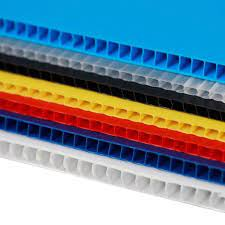

Polyethylene is a type of plastic commonly used in the production of corrugated plastic boxes. It is known for its flexibility, durability, and resistance to moisture. Polyethylene boxes are lightweight, making them easy to handle and transport. They provide excellent protection for goods during storage and shipping. With its versatile nature, polyethylene is widely used in various industries, including retail, agriculture, and logistics.

Polyethylene is a type of plastic commonly used in the production of corrugated plastic boxes. It is known for its flexibility, durability, and resistance to moisture. Polyethylene boxes are lightweight, making them easy to handle and transport. They provide excellent protection for goods during storage and shipping. With its versatile nature, polyethylene is widely used in various industries, including retail, agriculture, and logistics.

Polypropylene is another type of plastic used in corrugated plastic boxes. It is known for its high strength and rigidity, making it suitable for heavy-duty applications. Polypropylene boxes offer exceptional resistance to impacts, chemicals, and moisture. They are commonly used in industries where durability and protection are crucial, such as automotive, electronics, and food packaging. Polypropylene boxes provide a reliable solution for storing and transporting goods securely.

Both polyethylene and polypropylene offer unique advantages for corrugated plastic boxes, allowing businesses to choose the material that best suits their specific needs and requirements.

Polyethylene: Chemical Properties

Polyethylene, a widely used polymer, possesses unique chemical properties that make it an ideal material for corrugated plastic boxes. With its chemical formula (C2H4)n, polyethylene consists of long chains of repeating ethylene monomer units. The chemical structure of polyethylene is characterized by its saturated carbon backbone, which results in a high degree of flexibility and resilience. The presence of the ethylene monomer, with its double bond (C=C), allows for the polymerization process to occur, forming a long-chain polymer.

Furthermore, the chemical properties of polyethylene contribute to its suitability for corrugated plastic boxes. Polyethylene exhibits excellent chemical resistance, protecting the contents of the box from potential interactions with external substances. Its non-reactive nature ensures that the box maintains its structural integrity and does not deteriorate when exposed to various chemicals. Moreover, polyethylene is impermeable to water and offers resistance against moisture, making it an ideal choice for packaging applications.

The combination of these chemical properties makes polyethylene an excellent material for corrugated plastic boxes, providing durability, protection, and versatility for various industries.

Polypropylene: Chemical Properties

Polypropylene (PP) is a thermoplastic polymer characterized by its unique chemical properties, which make it an ideal material for corrugated plastic. Its chemical formula is (C3H6)n, where “n” represents the number of repeating units in the polymer chain. The chemical structure of PP consists of propylene monomers joined together through covalent bonds. This linear arrangement of carbon and hydrogen atoms provides polypropylene with excellent chemical resistance, making it resistant to acids, bases, and solvents. This property ensures that corrugated plastic boxes made from PP can safely store a wide range of products without the risk of chemical reactions or deterioration.

Polypropylene (PP) is a thermoplastic polymer characterized by its unique chemical properties, which make it an ideal material for corrugated plastic. Its chemical formula is (C3H6)n, where “n” represents the number of repeating units in the polymer chain. The chemical structure of PP consists of propylene monomers joined together through covalent bonds. This linear arrangement of carbon and hydrogen atoms provides polypropylene with excellent chemical resistance, making it resistant to acids, bases, and solvents. This property ensures that corrugated plastic boxes made from PP can safely store a wide range of products without the risk of chemical reactions or deterioration.

Moreover, the chemical composition of polypropylene contributes to its desirable properties for corrugated plastic boxes. The high melting point of PP, around 160-165°C, ensures that the boxes can withstand elevated temperatures during storage and transportation without deformation or structural damage. Additionally, the lightweight nature of polypropylene allows for easy handling and transportation of corrugated plastic boxes.

The combination of these chemical properties, along with its durability and resistance to impact and moisture, makes polypropylene an excellent choice for corrugated plastic boxes used in various industries, including packaging, storage, and transportation.

Comparing Polypropylene and Polyethylene: Key Differences

The physical properties of packaging materials play a crucial role in the efficiency and cost-effectiveness of logistics operations, making it essential for logistics companies, retailers, and packaging manufacturers to carefully evaluate their options.

In the table, we examine the key differences in physical properties between polyethylene and polypropylene, two commonly used materials for corrugated plastic boxes.

By understanding the strengths and limitations of each material, businesses can make informed decisions that align with their specific needs and contribute to cost savings in the long run.

| Properties | Polyethylene | Polypropylene |

|---|---|---|

| Strength | Polyethylene exhibits good strength and impact resistance, making it suitable for handling heavy loads and providing protection to products during transportation and storage. | Polypropylene offers excellent strength and toughness, allowing it to withstand rigorous handling and provide reliable protection to products. |

| Flexibility | Polyethylene is known for its flexibility, allowing it to conform to various shapes and contours. This flexibility makes it easier to handle and stack corrugated boxes, optimizing storage space. | Polypropylene also exhibits flexibility, enabling it to be easily folded and manipulated for efficient handling and storage. |

| Rigidity | While polyethylene is generally more flexible, it can still provide adequate rigidity for packaging needs, maintaining the structural integrity of the boxes. | Polypropylene offers a higher level of rigidity, providing sturdiness and stability to the corrugated boxes, especially when handling heavier loads. |

| Heat Resistance | Polyethylene has good heat resistance, maintaining its structural integrity and strength at moderate temperatures. | Polypropylene has a higher heat resistance than polyethylene, allowing it to withstand higher temperatures without deforming or losing its properties. |

| Cold Resistance | Polyethylene displays excellent cold resistance, remaining tough and durable even in freezing temperatures. | Polypropylene exhibits superior cold resistance, retaining its strength and flexibility in extremely low temperatures, making it suitable for cold storage applications. |

| Moisture Barrier | Polyethylene provides a reliable moisture barrier, preventing water and moisture from permeating the boxes and damaging the contents. | Polypropylene also offers a good moisture barrier, effectively protecting the products from moisture-related damage during transportation and storage. |

| Chemical Resistance | Polyethylene has excellent chemical resistance, making it resistant to most chemicals, acids, and bases commonly encountered in packaging applications. | Polypropylene demonstrates high chemical resistance, withstanding a wide range of chemicals and solvents without degradation or loss of properties. |

| Recyclability | Polyethylene is highly recyclable, contributing to sustainable packaging practices and reducing waste. | Polypropylene is also recyclable, supporting environmental initiatives and promoting a circular economy. |

| Cost Comparison | Corrugated polyethylene boxes are cost-effective, providing an affordable packaging solution for retailers and manufacturers. | Corrugated polypropylene boxes may have a higher cost compared to polyethylene due to the material’s enhanced strength and durability. However, the long-term savings in terms of product protection and reduced replacement costs can outweigh the initial investment. |

The information provided in the table gives a comprehensive overview of the key differences between polyethylene and polypropylene in terms of their physical properties and how they can benefit retailers and packaging manufacturers. Understanding these differences is essential for making informed decisions when selecting the most suitable material for corrugated boxes.

While the table covers the basics, there may be more specific considerations or nuances to explore based on individual requirements. Therefore, for a deeper understanding and to make the best choice for your business or individual packaging needs, we recommend further research and consulting with experts like those at Brandt Box.

1. Physical Properties: Examining Strength, Flexibility, and Rigidity

When it comes to selecting the right material for corrugated plastic boxes, understanding the physical properties of polypropylene and polyethylene is crucial. By comparing these properties, businesses can make informed decisions that align with their specific needs and help reduce costs in the long run.

- Strength: Polypropylene exhibits high tensile strength, making it resistant to deformation and able to withstand heavy loads. Polyethylene also has good strength properties, but it may not be as strong as polypropylene in certain applications.

- Flexibility: Polyethylene offers excellent flexibility, allowing it to bend and conform to different shapes without breaking. Polypropylene is less flexible than polyethylene but still possesses sufficient flexibility for many packaging applications.

- Rigidity: Polypropylene is known for its rigidity, providing structural integrity and stability to corrugated plastic boxes. Polyethylene, while generally less rigid than polypropylene, can still offer adequate rigidity depending on the specific grade and thickness used.

Understanding these key differences empowers businesses to make informed decisions, optimize their packaging solutions, and ultimately reduce costs without compromising on the quality and functionality of their corrugated boxes.

2. Heat Resistance: Comparing Performance in High-Temperature Environments

When it comes to selecting the right material for corrugated plastic boxes, considering heat resistance is essential, especially for businesses operating in high-temperature environments. Both polypropylene and polyethylene offer different levels of heat resistance, which can impact their performance and durability.

Understanding the differences between these materials can help businesses make informed decisions that not only meet their specific needs but also contribute to cost reduction and operational efficiency.

- Polypropylene:

- Good heat resistance, with a melting point of approximately 130°C (266°F).

- Can withstand higher temperatures compared to polyethylene.

- Exhibits excellent dimensional stability at elevated temperatures.

- Polyethylene:

- Moderate heat resistance, with a melting point ranging from 115°C to 135°C (239°F to 275°F), depending on the grade.

- Not as heat-resistant as polypropylene.

- May deform or melt at higher temperatures.

The comparison of heat resistance properties between polypropylene and polyethylene demonstrates the significance of selecting the appropriate material for corrugated plastic boxes in high-temperature environments. Polypropylene’s superior heat resistance and dimensional stability make it a favorable choice when exposure to elevated temperatures is a concern.

The comparison of heat resistance properties between polypropylene and polyethylene demonstrates the significance of selecting the appropriate material for corrugated plastic boxes in high-temperature environments. Polypropylene’s superior heat resistance and dimensional stability make it a favorable choice when exposure to elevated temperatures is a concern.

By utilizing polypropylene for heat-sensitive applications, businesses can reduce the risk of deformation or melting, ensuring the integrity of their packaging solutions and minimizing potential costs associated with product damage or loss.

3. Cold Resistance: Assessing Performance in Low-Temperature Conditions

When it comes to the cold resistance of materials used in corrugated plastic boxes, both polypropylene and polyethylene exhibit favorable performance in low-temperature conditions. However, there are some differences worth noting.

Polypropylene demonstrates exceptional cold resistance, maintaining its structural integrity and mechanical properties even in extremely low temperatures. This makes it a suitable choice for applications requiring prolonged exposure to freezing environments.

On the other hand, polyethylene also exhibits good cold resistance, but its performance may vary depending on the specific grade and formulation. In general, it is important to consider the intended use and the expected temperature range to ensure the selected material can withstand cold conditions without compromising its functionality.

Overall, both polypropylene and polyethylene offer reliable cold resistance properties, making them reliable options for corrugated plastic boxes in various cold storage and transport applications.

4. Moisture Barrier: Analyzing Water and Moisture Resistance

When it comes to choosing the right packaging material for businesses, understanding the moisture barrier properties of different options is crucial.

When it comes to choosing the right packaging material for businesses, understanding the moisture barrier properties of different options is crucial.

In this comparison between polypropylene and polyethylene, we analyze their water and moisture resistance capabilities, highlighting how they can help reduce costs for businesses.

- Polypropylene:

- Offers a high level of moisture resistance, providing a reliable barrier against water and moisture infiltration

- Helps to protect products from moisture-related damage, such as warping, mold, or mildew

- Prevents water absorption, ensuring the integrity of the packaging and the quality of the enclosed items

- Reduces the risk of product spoilage or degradation caused by exposure to moisture

- Helps businesses avoid potential losses due to damaged or compromised goods

- Polyethylene:

- Exhibits excellent water and moisture resistance properties, making it highly suitable for packaging applications

- Forms an effective barrier against water vapor, preventing moisture from seeping into the packaging

- Guards against the negative effects of moisture, such as corrosion, decay, or deterioration of packaged items

- Reduces the need for additional protective measures or moisture-absorbing materials

- Contributes to cost savings by minimizing the risk of product damage and the associated financial losses

The moisture barrier properties of polypropylene and polyethylene in corrugated plastic boxes offer businesses a valuable advantage. By effectively preventing water and moisture infiltration, these materials protect packaged items from damage and deterioration, minimizing the risk of financial losses. Choosing the appropriate material with excellent moisture resistance can lead to cost savings by avoiding the need for costly replacements, repairs, or customer dissatisfaction.

The moisture barrier properties of polypropylene and polyethylene in corrugated plastic boxes offer businesses a valuable advantage. By effectively preventing water and moisture infiltration, these materials protect packaged items from damage and deterioration, minimizing the risk of financial losses. Choosing the appropriate material with excellent moisture resistance can lead to cost savings by avoiding the need for costly replacements, repairs, or customer dissatisfaction.

5. Chemical Resistance: Evaluating Resistance to Various Chemicals

When it comes to selecting packaging materials for businesses, understanding the chemical resistance properties of different materials is crucial. In this comparison of polypropylene and polyethylene, we will evaluate their chemical resistance capabilities, focusing on how they can help reduce costs for businesses.

By choosing the right material with excellent chemical resistance, businesses can minimize the risk of product damage, contamination, and the need for additional protective measures, ultimately saving costs in the long run.

- Polypropylene:

- Can withstand exposure to acids, bases, oils, and other corrosive substances without degradation

- Reduces the risk of damage or contamination of products during storage or transportation

- Minimizes the need for additional protective measures or costly secondary packaging

- Polyethylene:

- Resistant to acids, alkalis, oils, and various chemical substances

- Provides a reliable barrier, preventing chemical reactions or leaks that could compromise product quality

- Reduces the risk of cross-contamination or damage to other items stored or transported together

- Eliminates the need for expensive specialized packaging for chemical-sensitive products

The chemical resistance properties of polypropylene and polyethylene offer significant cost-saving benefits for businesses. Both materials demonstrate excellent resistance to various chemicals, protecting products from damage, leaks, and contamination.

By utilizing corrugated plastic boxes made from these materials, businesses can reduce the need for costly secondary packaging and additional protective measures.

6. Recyclability: Assessing the Recyclability and Environmental Impact

When comparing polypropylene and polyethylene, one important aspect to consider is their recyclability and environmental impact. Both materials offer the benefit of being recyclable, allowing them to be transformed into new products instead of ending up in landfills. This not only contributes to environmental sustainability but also presents cost-saving opportunities for businesses.

- Polypropylene:

- Recyclable: Polypropylene can be recycled and processed into new products.

- Widely accepted: Many recycling facilities accept polypropylene for recycling.

- Energy-efficient: Recycling polypropylene consumes less energy compared to producing new plastic.

- Reduced environmental impact: Recycling polypropylene helps reduce waste and conserve resources.

- Polyethylene:

- Recyclable: Polyethylene is recyclable and can be turned into new products.

- Commonly recycled: Many recycling programs accept polyethylene for recycling.

- Environmental benefits: Recycling polyethylene reduces the need for virgin plastic production and decreases waste in landfills.

- Conservation of resources: Recycling polyethylene helps conserve energy and raw materials.

The recyclability of polypropylene and polyethylene brings significant advantages to businesses. By choosing these materials for packaging, such as corrugated plastic boxes, companies can reduce their environmental footprint and contribute to a circular economy.

Cost Comparison of Polyethylene and Polypropylene

When it comes to packaging materials, corrugated plastic boxes made from polyethylene and polypropylene offer various benefits. However, it’s crucial for businesses to assess the cost aspect before deciding which material to use.

By understanding the cost comparison between polyethylene and polypropylene for corrugated plastic boxes, companies can make informed choices that align with their budget and optimize their packaging solutions.

| Material | Cost per Box (USD) | Application Examples |

|---|---|---|

| Polypropylene | $5-15 per box | Packaging materials, automotive parts |

| Polyethylene | $3-10 per box | Plastic bags, containers, pipes |

High-density polyethylene (HDPE) and low-density polyethylene (LDPE) offer cost advantages and widespread availability, making them popular choices for businesses seeking to optimize packaging expenses.

On the other hand, polypropylene (PP) exhibits high resistance to chemicals and durability, making it suitable for demanding applications. By carefully evaluating packaging requirements, budget constraints, and desired properties such as high resistance and cost-effectiveness, businesses can make informed decisions that strike the optimal balance between cost and performance, ensuring efficient and effective packaging solutions for their products.

Discover the Difference with Brandt Box’s High-Quality Corrugated Plastic Boxes

Corrugated plastic boxes offer the same durability and versatility as other shipping containers. Understanding the differences between polyethylene and polypropylene is crucial in selecting the best packaging for your products.

Polyethylene is known for its lightweight, strength, and cost-effectiveness, making it a popular choice in many industries. However, it has limitations when it comes to exposure to high temperatures or UV rays.

On the other hand, polypropylene excels in withstanding temperature extremes and offers excellent protection against elements like oils. This makes polypropylene a suitable material for a range of applications. It provides the necessary durability and performance, especially in environments that require resistance to low temperatures and a high melting point.

When choosing between the two materials, it’s essential to consider your specific needs. At Brandt Box, we offer a wide selection of corrugated plastic boxes in both polyethylene and polypropylene, allowing you to find the perfect product for your requirements.

We also provide customization services beyond standard sizes. If you need further advice on choosing the right material for your project, feel free to contact us with any questions.

FAQ

Can polyethylene and polypropylene be recycled?

Yes, both polyethylene and polypropylene can be recycled. They are commonly recycled plastics and are widely accepted by recycling facilities.

Which material is stronger, polyethylene or polypropylene?

Polypropylene generally has a higher level of strength and rigidity compared to polyethylene. It is known for its durability and ability to withstand heavy loads.

Do polyethylene and polypropylene have different levels of flexibility?

Yes, polyethylene is generally more flexible than polypropylene. Polyethylene has a higher degree of elasticity and can bend and stretch more easily. On the other hand, polypropylene is stiffer and has less flexibility.